Seamless Steel Pipes

As the name suggests, seamless steel pipes have no seams or welded joints. There are no weaker or stress concentration areas in seamless pipes due to the absence of seam or welds.

So the seamless pipes have better and uniform mechanical properties along the cross-sectional axis. But producing a pipe without seam or weld increases its cost significantly.

Seamless steel pipes applications include areas where cost can be compromised over quality benefits like in high temperature and pressure applications in the oil and gas industry.

Specifications of seamless pipes

Oil Country Tubular Goods (OCTG) are used in oil and gas and manufactured according to API 5L Pipe ASTM standards. Others include ASTM A106 for high-temperature seamless pipes; ASTM A179, ASTM A192, ASTM A19, ASTM A210, ASTM A213 used for heat exchanger tubes; ASTM A333 used for mechanical applications; and ASTM A556 used for high-pressure applications like steam. The ASME B36.10 specification used to define pipe sizes and weights. Usually, seamless pipes have a diameter between 1/8 and 24 inches.

Manufacturing process

Three major methods are used for manufacturing seamless pipes. Mandrel Mill Process is the most common, where heated round steel billet is turned into a hollow cylinder by pressing it against the rotary piercer in the centre. Meanwhile, rollers control the outside diameter and thickness.

A modified form of this process is known as Plug Mill method. This process is almost the same as Mandrel Mills with a difference that the hollow cavity is produced through multiple passes in Plug Mill method.

The other method is known as Forged Seamless Pipe Manufacturing Process. It is used to produce high-pressure seamless pipes. In this process, the hollow cavity of the seamless pipe is produced through forging with a die which is equal to the internal diameter of the pipe.

Top seamless steel pipes manufacturing companies

Below are some selected seamless steel pipe and tube manufacturing companies.

- Angang Steel

- ArcelorMittal

- Baosteel

- Baotou Iron & Steel

- Chelyabinsk Pipe Rolling Plant (ChTPZ)

- Hunan Valin Iron & Steel

- Interpipe

- Nippon Steel & Sumitomo Metal Corporation (NSMC)

- Tenaris

- Ternium

- Tianda Oil Pipe (V&M)

- Tianjin Pipe

- TMK

- US Steel

- USS

- V&M Tubes

- Vizag Steel

Market overview

Seamless pipes are mostly used in oil and gas exploration activities. Oil prices are recovering after a huge decline in 2016. Since then, oil prices recovered modestly which underpinned the OCTG market as well. Production cuts and quota agreement between OPEC and non-OPEC countries played a vital role in stabilising the oil market, among other factors.

The low supply trends are creating opportunities for new exploration activities. Several factors are disrupting the supply chains in oil and gas. Geopolitical problems in Venezuela and Iran and exit of Qatar from OPEC are expected to influence the supply in the next few years. Oil reservoirs in existing fields are depleting with high rates and new exploration demands are rising which will affect the OCTG markets positively in future.

The automotive sector is also a major user of small diameter seamless tubes. Electrification trends in the auto industry are changing the face of the market. The auto industry is relocating and shifting towards developing markets. The EU is the second-largest vehicle producer after China. Other major auto producers are Japan, India, South Korea, the US, Brazil, Mexico, Canada and Iran. So, the demand for seamless pipes will see more growth opportunities in these key markets.

Other major end-use sectors of seamless pipes are construction and infrastructure sectors. According to the UK’s Institution of Civil Engineers (ICE), the UK construction market will grow faster than China over the next decade. The Chinese construction market has still huge growth potential due to its new urbanisation policies.

End-users of seamless pipes

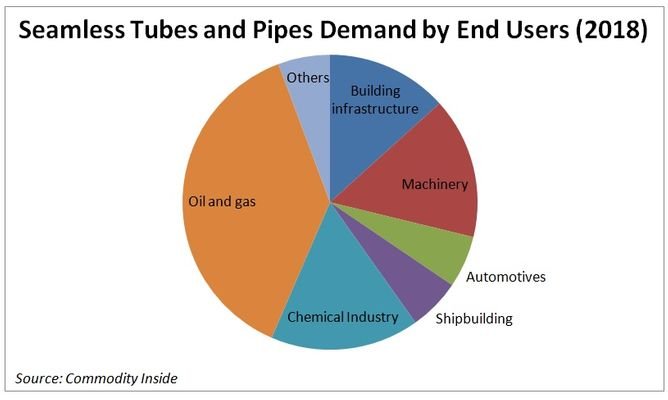

Oil and gas sector is one of the largest end-user of OCTG pipes. The oil and gas sector accounted for around 37% share in the total seamless pipes as of 2018.

Chemical industry and mechanical engineering or machinery sectors also have major shares in seamless pipes demand. Here, seamless pipes are used in high temperature and pressure lines like boiler tubes.

Automotive sector consumes small and precision diameter seamless tubes in radiator tubes, staring rods etc. Construction and infrastructure sector also account for a substantial share in the seamless pipes demand. Its applications include scaffoldings, water and steam lines, loading components and poles.

About Commodity Inside Tube and Pipes Capabilities:

Commodity Inside has a vast experience in the steel pipes and tubes market. We have a number of off the shelf reports on the pipe and tube industry. We also provide consulting and bespoke studies. Our initial scoping assessment is free of costs. Please contact us now about your query at Research@commodityinside.com